【Exclusive Interview】Part 2 : James Zorab – Lowland Bond – Edinburgh Whisky

- 造り手

- 樽・蒸留器・倉庫

Lochlea Distillery could become the world’s first wholly on-site farm-type distillery anytime soon. Complemented and forged by Ayrshire, Scotland’s beautiful nature, and plentiful resources, Lochlea whisky represents this young distillery’s passion for ultimate local whisky. By guaranteeing absolute transparency about its production and ingredients, and with unique characters in whisky and distillery, Lochlea Distillery is rapidly growing in popularity.

This distillery was established on the Lochlea farm, which took care of cows and grew barley on the side to feed them. As the farm owner, Neil McGeoch considered this farm business a low-return and rigid job type; he decided to try expanding the barley growth and transitioning into some other industry.

By rejuvenating their buildings and repurposing them into a distillery, Lochlea Distillery began its production in 2018.

Lochlea Distillery: Owner Neil and Commercial Manager David

As an independent family owned farm and distillery, Lochlea Distillery sources all its barley from its field. Also, Lochlea is in the middle of designing its legacy and tradition, which they aim to be a 100% on-site farm-type distillery. Although there are some distilleries, such as Spring Bank or Bruichladdich, do something similar, once Lochlea Distillery is able to complete the malting process by itself, they would be the very first Scotch whisky maker to complete everything, from sowing the seeds to bottling, at one single site. Lochleas’ ultimate goal would lead them to creating a unique whisky entirely for them and the region, representing Ayrshire, Scotland, through local ingredients and a maturing atmosphere.

| Distillery | Lochlea Distillery |

| Owner | Neil McGeoch |

| Location | Lochlea Farm, Craigie, Kilmarnock KA1 5NN, United Kingdom |

| Year of Establishment | 2018 |

| Website | Lochlea Distillery |

| Contact | Email:info@lochleadistillery.com Telephone:01668 281554 |

| Social Media | Instagram:@lochleawhisky Facebook:@lochleawhisky X:@LochleaWhisky |

Lochlea Distillery and its farm is located in South Ayrshire, Scotland, around 40 minutes drive from Glasgow. However, Lochlea Distillery does not have a visitor center or a distillery shop since they are not open to the public.

Their core single malt whisky is made from their own barley using the natural resources of the Lochlea farm. It is non-chill filtered, and no colorings are added. “Lochlea Cask Strength” is also available and will be released for every batch.

Barley harvested at Lochlea

There are four editions: Sowing, Harvest, Fallow, Ploughing

Each edition represents one of the four seasons expressed and implemented through thoughtful cask choices. Each crop would have these editions and cycles around. At the moment, they are up to Fallow Edition (Second crop).

Lochlea products.

For more information, click here.

David works as the Commercial Manager at the Lochlea Distillery. He has over ten years of experience in the whisky industry with expertise in cask sales and buying, from his past experience in Beam Santory and Douglas Lang. Currently, he is in charge of sales and marketing of the Lochlea whisky.

David kindly showed us around the distillery!

David:

This is a farm field where we grow and harvest all of our barley. We have 222 acres of area, which, in total, we get around 600 tons of barley, producing 200,000 liters of alcohol. Since nothing comes from other sources, how much we harvest from the field would directly influence our annual production as a distillery.

Separated into three bays, each contains 200 tons of barley.

David:

Lochlea Distillery employ traditional Scottish floor malting techniques. Each spring, we lay out a whole floor for six weeks of hands-on traditional turning. Currently, this hand-malted barley covers about 15% of the entire production. We are planning to expand this process when staffing allows. For the remaining 85% of the malts, we work with a local maltster called Bairds Malt.

Our Production Director, John Campbell, has rich experience with floor malting since he worked at Laphroaig as a Distillery Manager.

John Campbell at the barley warehouse.

David:

Our mill holds 1-ton of barley at a time, which we run twice a day. Once the mill gets low and needs a fill, people pick it up, take it around to the malt bins, fill it up, and return to reload. Our grist ratio is roughly 30% husk, 60% grit, and 10% flour. We control this by adjusting the distance between the rollers. We have to manage this for every delivery base of malt changes since even though it might come from the same batch, it’s never the same harvest. We check them almost weekly for the best flavor and efficiency ratio to achieve consistent flavor.

David:

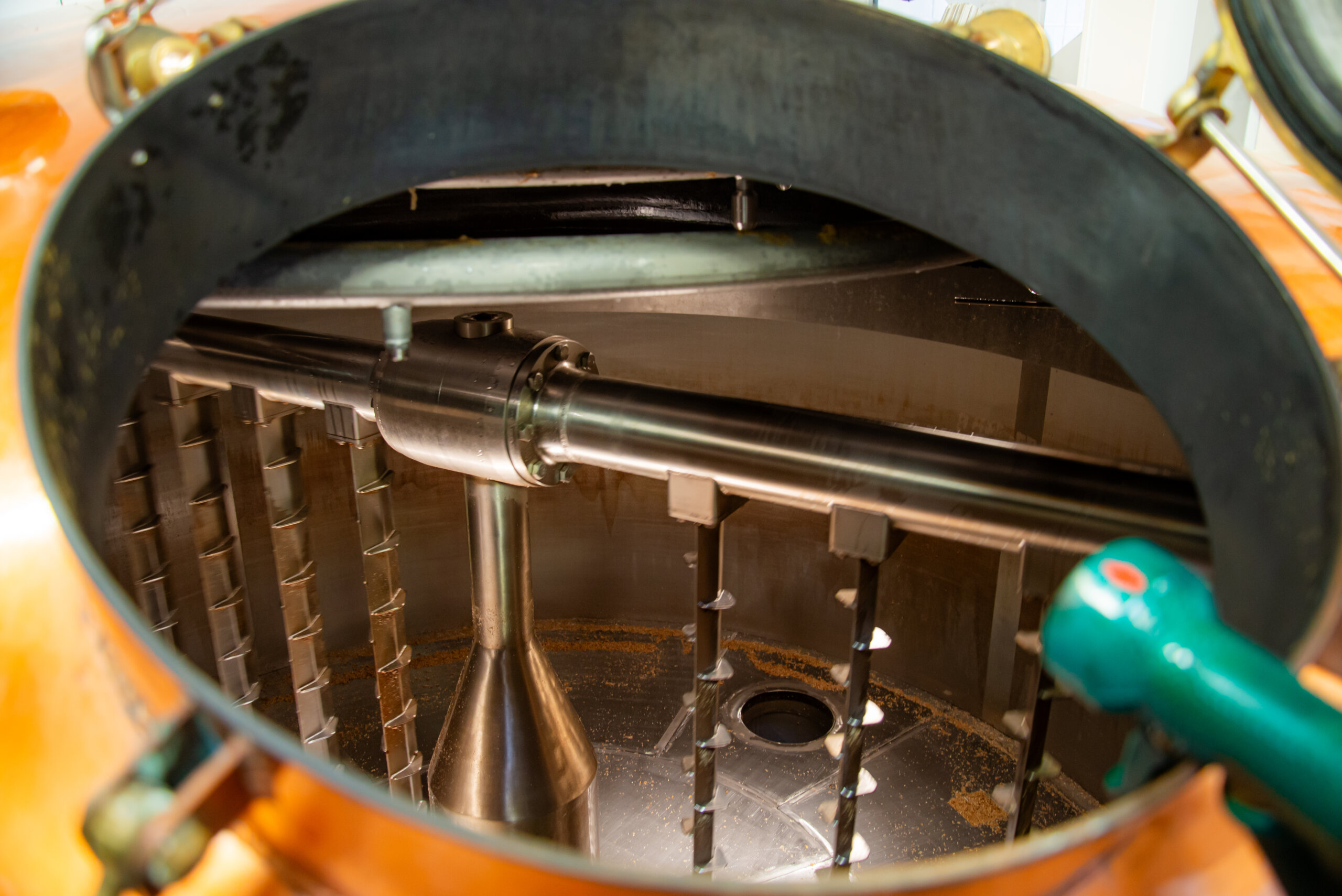

This is a 2-ton semi lauter mash tun. The goal here is to pull through that cereal character, to have a perfectly balanced new make spirit full of juicy fruit and cereal biscuits underneath. Because we understand our ingredients better than any other distilleries, we are capable of flourishing its flavor to its fullest potential. We change our grist ratio every delivery base. Although it may be the same batch, it’s never the same harvest. So we check it every week to make sure we are getting it right. We have to get the best efficiency to flavor ratio.

Owning a 2-ton mash allows us future production expansion if needed, without any additional construction.

2-ton semi lauter mash tun.

David:

We have 6 Douglas Fir Washbacks here, capacity of 15,000 liters each. Through a lot of experiments from fermentation lengths, yeast types, to amount of yeasts we have designed our recipe to do two short, 66 hours, and three long, 116 hours, fermentation. This way we get more prominent fruity notes, such as oranges or pears, from that longer fermentation.

In terms of the yeast type, after many trials, we decided on Maori yeast, since it gave us all the fruits that we wanted. Same with the yeast volume, we figured out that having slightly less yeast makes it work harder, and get more fruit as a result. Therefore, we only use one bag per washback, which is comparably less than usual.

Douglas Fir Washbacks

Dear WHISKY:

At what ABV (Alcohol by Volume) do you fill them?

David:

Fresh out the still, they lay around about 67-68%. From there, we often bring them down to 63.5%, that’s the strength that will go into most of the casks. We do that by adding a little bit of our own water from Lochlea. We do fill some casks at the strength that it comes out, but they would be most likely go into refill casks. If it’s something that’s quite active like these wine casks or a first-fill bourbon or sherry, we’ll bring the ABV down to 63.5. On the other hand, there are certain cask types where we fill them at very high ABV, 70%, for example.

David:

We have two unusually tall pot stills made by Forsyths to maximize reflux for fruitier and smoother spirits and adequately fit the building as this distillery has been repurposed. We manually cut it at 67% and re-distill the products from head and tail cuts. When John joined us, he slightly changed our process to heat up very slowly in the morning and gradually build up the steam.

George, their distiller carefully watching where to cut.

David: Doing this allows us to prolong all those nice juicy fruit flavors without burning them off early on. This distilling process would take about three hours as we intentionally run them relatively slowly to get plenty of copper contact. Longer copper contact would allow the spirits to have more chemical reactions between spirits’ unwanted flavors and copper, resulting in smoother liquid more depth, oiliness, and character.

Many people wonder if the washbacks would get inferred by the temperature of the stills since they are close to each other, but we have done a lot of research and experiments to make sure they are perfectly fine and would not interfere with each other. However, we are considering putting a jacket over the stills to ensure it is alright.

David:

We Fill around 30 casks every week. Every cask will come in here and get weighed as they are filled by hand. Fresh out the still, spirit lay around about 67-68%. From there, we bring them down to 63.5%, the strength that will go into the casks. This is done by adding a little bit of our own water from Lochlea. We do fill some casks at the strength that it comes out, but they would be most likely go into refill casks. If it’s something that’s quite active like these wine casks or a first-fill bourbon or sherry, we’ll bring the ABV down to 63.5.

Place where they hand-fill the cask.

David:

Our water here is very soft and clean even before filtering, unlike the water in the Highlands where there’s lots of salt or minerals left. Hence a lot of the bottled water that Scotland exports is all from this region.

One of the cleanest and softest water in Scotland

David:

There are three warehouses, where every 7,000 casks are barcoded to track its lifecycle. There are so many casks out on the floor right now because John was putting together our next batch. John was here this morning, nosing through all these casks to decide which ones were going in to devise a smaller volume recipe.

Casks stored neatly inside the maturation warehouse

David:

Small bottling hall inside the distillery allows us to bottle not all, but some releases such as single casks.

With its spectacular single-site farm-type whisky production, Lochlea Distillery is thriving daily to its goal through refinement of products and international expansion marketing. On top of their unique philosophy, Lochlea seeks originality through commitment towards their production processes and local ingredients resulting in extraordinary flavors. Unlike any other distillery worldwide, Lochlea truly embodies unique story and qualities of a local taste.